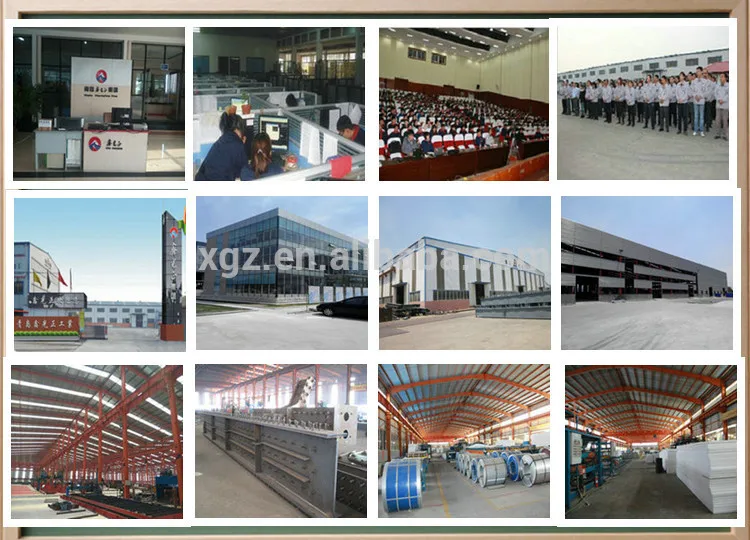

- Qingdao XGZ Steel Structure Co.,Ltd

- This is a verified supplier can provide quality products and have passed the Business License Check.

Home>Products>Construction building materials>XGZ Lightweight insulated EPS sandwich cement panel

XGZ Lightweight insulated EPS sandwich cement panel

- XGZ

- Shandong, China (Mainland)

- 200 Square Meter/Square Meters

- US $11 - 28/ Square Meter

- After the payment 20days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 3000 Square Meter/Square Meters per Day

-

Qingdao XGZ Steel Structure Co.,Ltd2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Qingdao XGZ Steel Structure Co.,Ltd2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Details

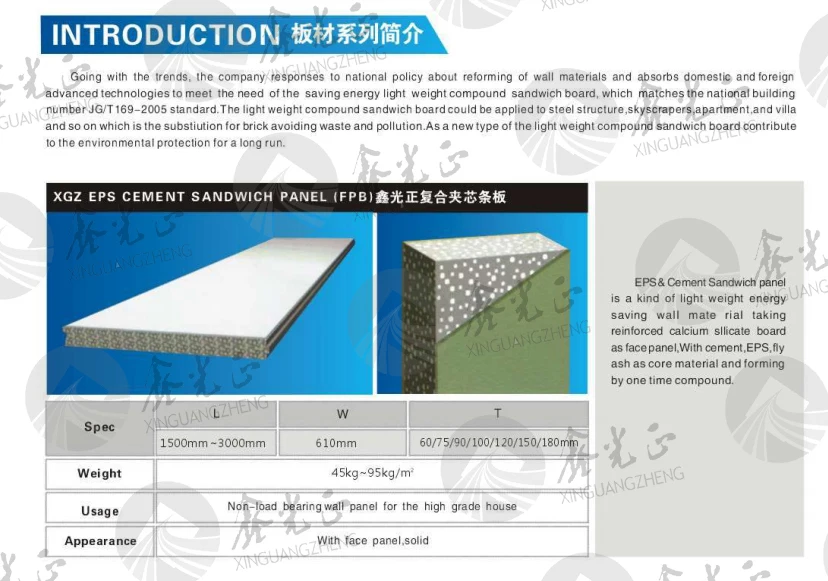

| Place of Origin: | Shandong, China (Mainland) | Brand Name: | XGZ | Model Number: | XGZ-FPB |

| Panel Material: | Nonmetal | Type: | EPS Sandwich Panels | Color: | Grey |

| Material: | EPS+CSB | Constrcution speed: | Fast | Anti-earthquak: | 8 degrees |

| Fireproof: | more than 4 hours | Use: | pre house, bedroom,Villa,living room,etc |

Product Description

XGZ Lightweight insulated EPS sandwich cement panel

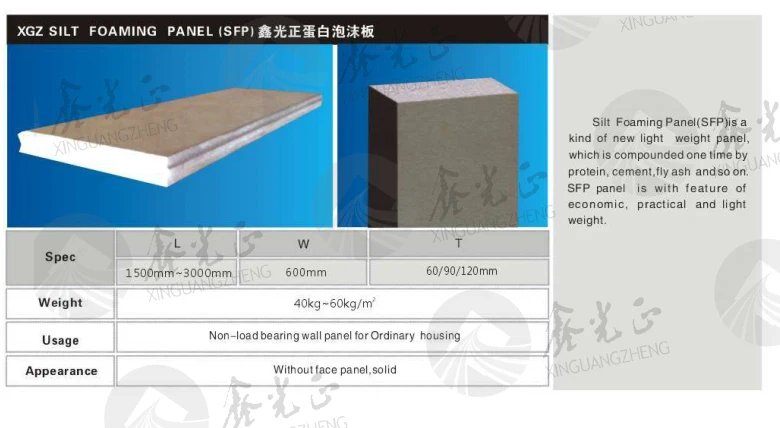

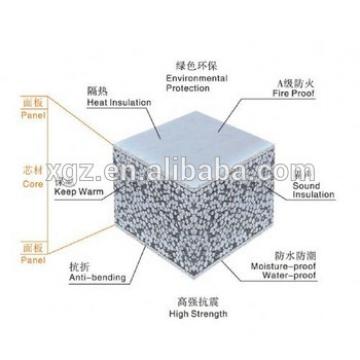

1.Energy Saving, Excellent Performance

Heat Preservation: Major material for wall panel is anti-freezing, heat preserving and environmental friendly.

Heat Insulation: Adjust the indoor temperature at a constant range.

Fire Proof: Both face sides with 4.5mm calcium-silicon fire proof board, thus XGZ Eps and Cement sandwich panel can be against a high temperature of 1000°C for 4 hours.

Water Proof: Tests has proved that water containers can be made by XGZ Eps and Cement sandwich panel without absorbing functions and no leakage at all.

Sound Insulation: The inside of XGZ wall panel material (EPS polystyrene grain) has fine sound insulation and sound-absorbing functions.

2. Easy Construction Process

Easy to Install: Using our installation material (PU Foam and Cement Adhesive) is easy to build house

Shorter Time: For a 50sq. house, using XGZ Eps and Cement sandwich wall panel, three people can finish it within ONE day, while using traditional block, it will take at least SEVEN days with ONE WEEK to finish.

3. High Security performance

High Intension: XGZ Eps and Cement sandwich wall panel can be nailed directly or have expansion bolt to lift and hang heavies, it can be covered by ceramic tile, wall paper, wood panel, coating etc.

Earthquake Resistance: The Seismic performance of XGZ Eps and Cement sandwich wall panel is at a magnitude of 8.5.

4.Space and Cost Saving

Space Saving: XGZ Eps and Cement sandwich wall panel with the thickness of 60mm-180mm, as a thin and solid new type construction material, it will save a lot of construction space compared with the traditional block.

Labor Cost Saving: As XGZ wall panel is easy and fast to construct.

Foundation Cost Saving: As the weight of XGZ wall panel is only 1/12 of traditional block, it will save 2/3 cost on construction structure

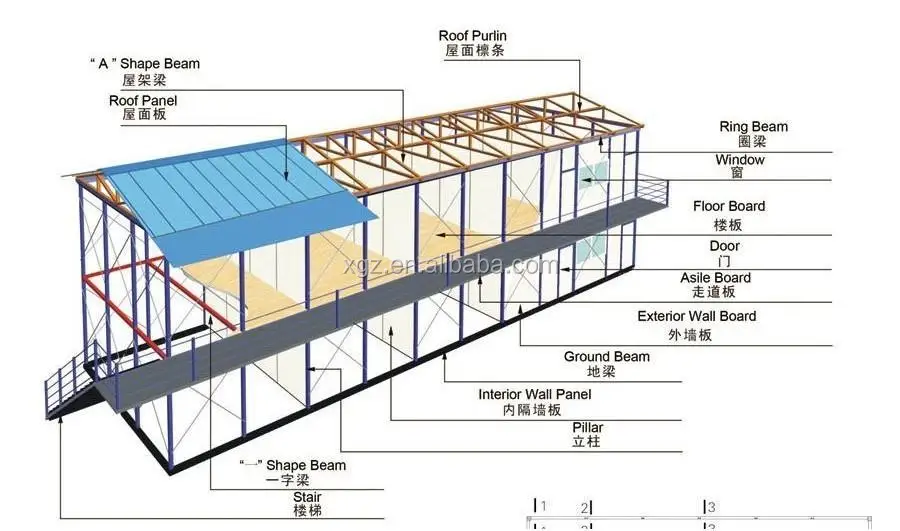

product specification

Main Material | |||||

Steel Structure &Wall Body | 1.Wall Stucture Frame | “U”Shape steel frame |

Roof& Ceiling | 1.Steel Roof Truss | C80x40x15x2 |

Concrete frame | 2.Roof Panel | Lightweight compound sandwich panel | |||

2.Exterior Wall | Lightweight compound sandwich panel | 3.RoofTile | Strip slate | ||

3.Exterior Wall Decorative Board | Imitation brick texture wall | 4.Ceiling | Decorative Mgo board Gypsum board | ||

4.Interior Wall | Lightweight compound sandwich panel |

Floor | 1.Floor Lateral Support | Round steel concrete | |

5.Interior Wall Decorative Material | Emulsion paint or tile | 2.Floor Grider | “H”steel | ||

6.Panel Used in Kitchen & Toilet | Lightweight compound sandwich panel | 3.Floor Panel | Lightweight compound sandwich panel | ||

7.Corner Post | Square tube concrete | 4.Floor Decorative Board | Tile or composite wooden floor panel | ||

8.Wall Pillar | Rectangular tube or concrete | 5.Toilet Ground Tile | Polished tile | ||

Note:About data is provided for reference.The real figurees are

basedon the customer's requirements and test report.

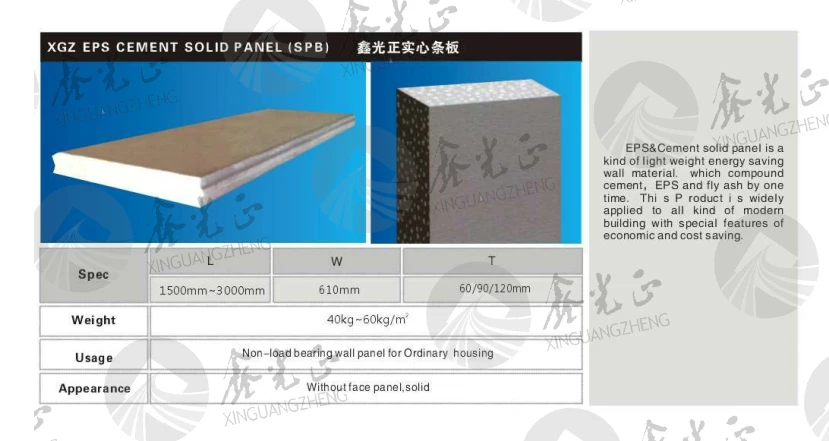

Composition:

1. Calcium silicate board(face panel)

2. Cement and EPS(core material)

3. Calcium silicate board(face panel)

Application:

Assembly houses, villas, public buildings, commercial buildings, residential houses, firewall, fire-rated warehouse, cold storage, etc.

EPS cement Sandwich panel can work as substitute of traditional construction materials such as brick, hollow brick etc

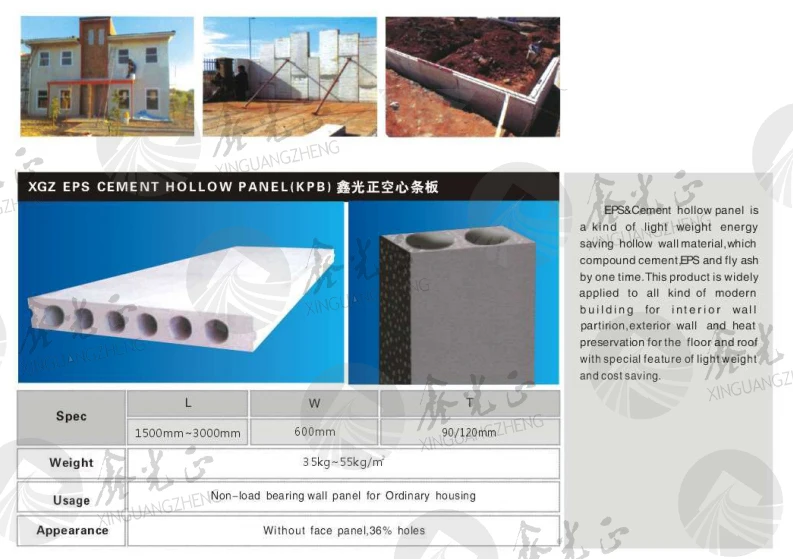

(1) Floor system

(2) Roof system

(3) Interior & Exterior wall system

(4) Villa Wall system

The construction process

The construction process

Steel building/warehouse/home/pre house/villa design and Quoted price , in order to give you a good design and Quoted price,appreciated if you can supply the followings:

1. Dimension: Length, width, height, eave height, roof pitch, etc.

2. Local climate: Wind speed, snow load, earthquake etc.

3. Your production process : According to your production process to design .

4. Roof and wall : PU/EPS/PVC Sandwich panel or color steel sheet .

5. Collecting light and ventilation : FRP-Lighting board and ventilation clerestory .

6. Doors and windows: Dimension, quantity, position to put them, Plastic steel or aluminum alloy .

7. Roof gutter : Stainless steel, galvanized steel, color steel plate .

WELCOME TO VISIT XGZ GROUP!

Contact Us

- Qingdao XGZ Steel Structure Co.,Ltd

- Emaila675991295@163.com

- AddressRuiping Center, Hongqi Road, Pingdu, Qingdao, China.

- Phone(Working Time)86-532-88336191

- WhatsApp15315573781

Related News

| Steel structure wareshoue install |

Product Categories

- aluminum composite panel

- Calcium Silicate board

- EPS

- steel structure villa

- mat

- template

- MODIFIED SHIPPING CONTAINER

- Putty

- External Wall Insulation Board

- Recommended Products

- Steel Structure Hangar

- Sandwich Panel

- Steel Structure Materials

- Crane

- Metal Processing Product

- Steel Structure Workshop

- Steel Structure Buildings

- Steel Garage/Carport

- Poultry House

- Prefab House/Villa

- Container House

- Construction building materials

- Crane Bridge

- DOORS AND WINDOWS

- CONTAINER LIVING ROOM

- CONTAINER RESTAURANT

- Steel Structure warehouse

- CONTAINER OFFICE

- prefab steel house

- prefab villa

- prefab house kits

- portable emergency shelter

- Steel structure mall

XGZ high quality wall panels interior sandwich panel cement

XGZ high quality wall panels interior sandwich panel cement XGZ commercial building products sandwich cement panel

XGZ commercial building products sandwich cement panel XGZ Cement & EPS carbon fiber composite sandwich panel

XGZ Cement & EPS carbon fiber composite sandwich panel XGZ Green Lightweigth easy install building materials

XGZ Green Lightweigth easy install building materials